CONTROLLED BOLTING & JOINT INTEGRITY

Isatta undertakes an array of on-site bolting services ranging from simple bolting of a single flange joint, to major construction, and maintenance of bolted joints of critical applications at shutdown. When it comes to joint integrity, ISL utilizes the highest-standard bolt torqueing and bolt tensioning technology.

Isatta expertise in joint integrity, measures and monitors bolt relaxation, gasket creep, direct load loss, friction variable reduction, and direct axial force. Our experts apply this understanding and skill set to each joint installation, understanding that every project demands various controlled bolting applications—from single flange installations and bolt tensioning requirements to scheduled turn-arounds and new construction.

Solutions

- Bolt Torqueing

- Bolt Torqueing

- Hot/Online Bolting

- Nut Splitting

- Bolt Load Validation

- Joint Breakout

SAFETY, TIME AND ACCURACY

Safe Operational Environment

Controlled bolting requires high level of skills and the critical need to follow prescribed operating procedures. Our skilled technicians’ maintain best safety standards by securing the designated work area before beginning operations, thus ensuring zero incidents due to human error.

Reduced Operating Time

Manual torqueing and bolt opening-closing techniques consume a lot of time and add to worker fatigue. Our procedure based systematic and calculated approach reduces the overall downtime and significantly improves productivity.

Bolt Load Accuracy and Consistency

Our combination of preliminary inspections, studies on bolting pattern required, controllable output settings, and use of tested and calibrated equipment ensures repeatable and consistent bold load accuracy.

.jpg)

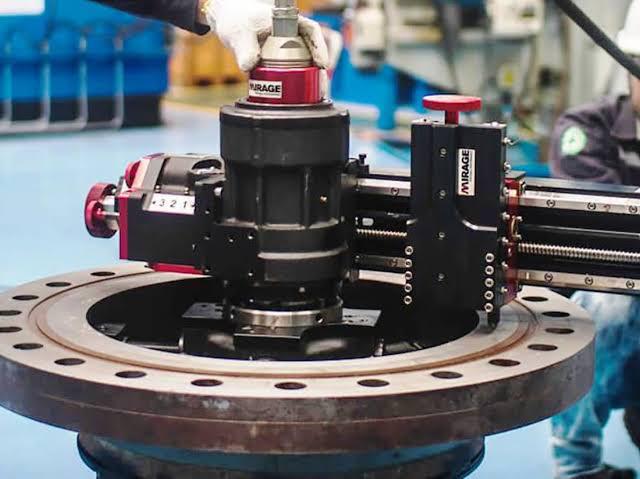

FLANGE MANAGEMENT

This is essential activity for a successful turn around maintenance plan. Flanges constantly experience damages form corrosion or erosion due to turbulence flow, impacts with other components during construction or installation or cuts from gaskets leaks.

Our Flange Management allows our clients to better maintain and refurbish pressure vessels, heat exchanger, bolted joints and valves. This will help in improving plant safety and the environmental performance of the plant. We provide clients with a leak-free startup and a detailed record of activities carried out during the turnaround.

Our services are supported by a robust Quality Management System and a Health, Safety and Environmental Management System. These systems ensure that the highest standard of service is continually achieved for clients and that environmental and safety legislative commitments relevant to the work environment and service provided are continually met.

Solutions are:

- Flange facing

- Flange Alignment

- Nut Splitting

- Flange Inspection

- Flange Spreading

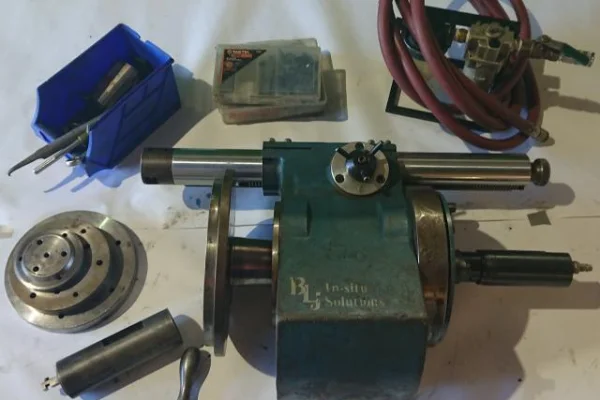

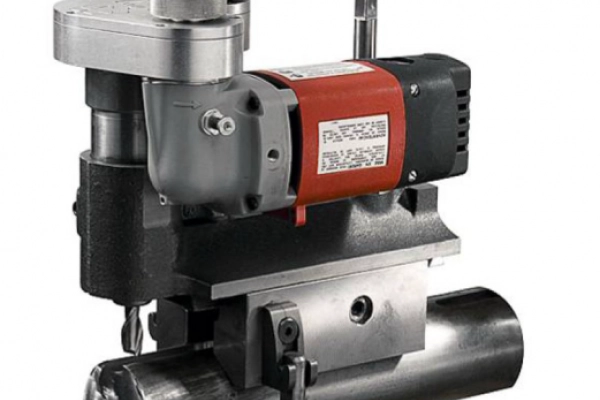

ON-SITE MACHINING EQUIPMENT HIRE OPTIONS

ISL In-situ Solutions carries one of the most comprehensive, dedicated and supported hire fleets.

- Journal Turning Lathe (Shaft Turning)

- Flange Facing Machines

- Keyway Milling Machine

- Magnetic Base Drills

- Pipe Cutting & Weld Prep Machines

- Quick Face Flange Facer

- Spot Facing Machine